Powerful Protection from Payment to Delivery

Secure and Reliable Payment

Money Back Guarantee

Shipping and Delivery

After-Sales Service

Enter the order reference number received by email to check the status or make payment.

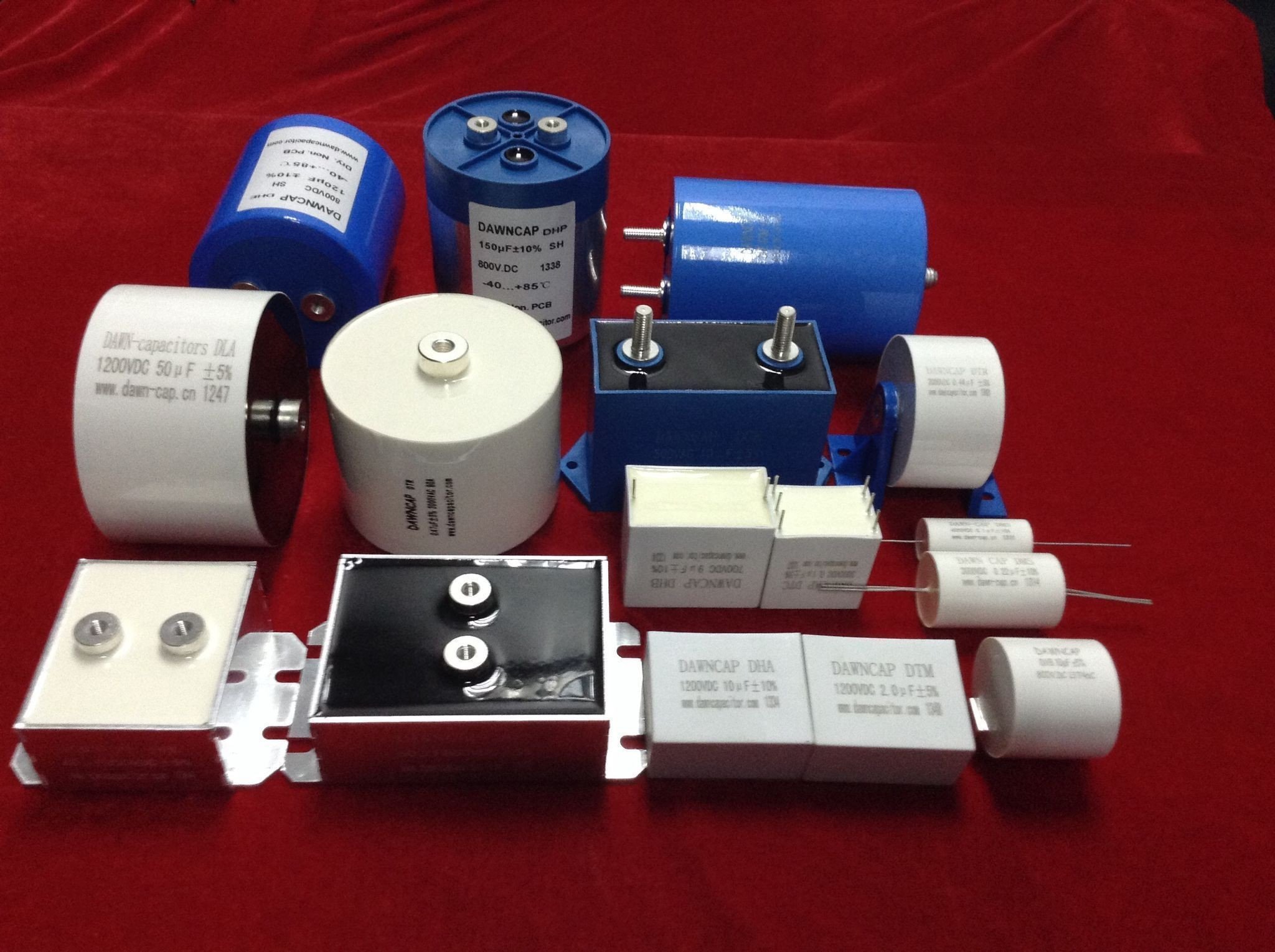

What are the commonly used capacitors? 9 categories

There are several types of commonly used capacitors:

1. Ceramic capacitors (CT) are inexpensive, have small capacitance, and are mainly used in low-frequency circuits.

2. Polyester capacitors (CL) have similar characteristics and uses as ceramic capacitors.

3. Mica capacitors (CC) are expensive, have small capacitance, and are stable in nature. They are generally used in high-frequency circuits.

4. Electrolytic capacitors (CD) have large capacitance and have positive and negative poles. They are mainly used in power circuits and pulsating circuits.

5. Mica capacitors (CY) have high voltage resistance (250v-450v), small capacitance, are expensive, and have a large volume. They are used in important parts of communication equipment.

There are also tantalum capacitors (CA), niobium capacitors (CN), film capacitors, and so on.

Types of Capacitors

- Electrolytic Capacitors

Electrolytic capacitors are made by rolling up absorbent paper with a paste-like electrolyte between two aluminum foils. The thin oxide film acts as the dielectric. These capacitors have polarity due to the unidirectional conductivity of the oxide film. They have a large capacitance and can withstand large pulsating currents, but have large capacitance errors and leakage currents. They are not suitable for use in high-frequency and low-temperature applications, and are not suitable for use in low-frequency bypass, signal coupling, or power filtering above 25kHz.

- Tantalum Capacitors

Tantalum capacitors use sintered tantalum as the positive electrode and solid manganese dioxide as the electrolyte. They have better temperature and frequency characteristics and reliability than ordinary electrolytic capacitors, especially with extremely low leakage current, good storage stability, long life, small capacitance errors, and small size. They have poor tolerance to pulsating currents and are prone to short circuits when damaged. They are ideal for use in ultra-small high-reliability components.

- Film Capacitors

Film capacitors have a structure similar to paper capacitors, but use low-loss plastic materials such as polyester and polystyrene as the dielectric. They have good frequency characteristics and low dielectric loss, but cannot be made into large capacitances and have poor heat resistance. They are suitable for use in filters, integrators, oscillators, and timing circuits.

- Ceramic Capacitors

Ceramic capacitors have a through-hole or pillar structure. One electrode is installed with a screw. They have very small lead inductance, good frequency characteristics, and low dielectric loss. They have temperature compensation and cannot be made into large capacitances. They are particularly suitable for high-frequency bypass.

- Monolithic Ceramic Capacitors

(Multi-layer ceramic capacitors) are made by coating several ceramic film blanks with electrode paste, stacking them together and winding them into an inseparable whole, and then sealing them with resin. They are small in size, large in capacity, high in reliability, and resistant to high temperatures. Low-frequency monolithic ceramic capacitors with high dielectric constants also have stable performance, small volume, and high Q value. They are suitable for use in noise bypass, filters, integrators, and oscillating circuits.

- Paper Capacitors

Paper capacitors generally use two aluminum foils as electrodes, separated by capacitor paper with a thickness of 0.008-0.012mm. They are easy to manufacture, inexpensive, and can achieve large capacitances. They are generally used in low-frequency circuits and cannot be used at frequencies higher than 3-4MHz. Oil-immersed capacitors have higher voltage resistance than ordinary paper capacitors and good stability, making them suitable for high-voltage circuits.

- Trimmer Capacitors

Trimmer capacitors can adjust the capacitance within a small range and can be fixed at a certain capacitance value after adjustment. Ceramic trimmer capacitors have a high Q value and small size. They are usually divided into cylindrical and disc types. Mica and polystyrene media usually use a spring structure, which is simple in structure but has poor stability. Wire-wound ceramic trimmer capacitors change the capacitance by removing the copper wire (outer electrode), so the capacitance can only be reduced and is not suitable for situations that require repeated adjustment.

- Ceramic Capacitors

Ceramic capacitors are made by extruding high dielectric constant capacitor ceramics (barium titanate-titanium dioxide) into cylindrical tubes, discs, or discs as the dielectric, and then using a silver-plated layer electrode sintering method. They can be divided into high-frequency and low-frequency ceramic capacitors. Capacitors with small positive temperature coefficients are used in high-stability oscillation circuits as loop capacitors and pad capacitors.

Low-frequency ceramic capacitors are limited to use in low-frequency circuits for bypass or DC isolation, or for situations with low stability and loss requirements (including high frequencies). These capacitors are not suitable for use in pulse circuits because they are prone to breakdown under pulse voltage. High-frequency ceramic capacitors are suitable for high-frequency circuits.

- Glass Glaze Capacitors

Glass glaze capacitors are made by spraying a special mixture suitable for spraying as a thin film, and then using a silver electrode layer sintering method to form a "monolithic" structure. They have performance comparable to mica capacitors, can withstand various weather conditions, and can generally work at temperatures of 200℃ or higher. The rated working voltage can reach 500V, and the loss is tgδ0.0005-0.008.

Recent Posts

Company

About UsContact UsTerms & ConditionsPrivacy StatementPayment,Shipping & InvoiceRefund & Return PolicyWarranty PolicyFrequently asked questionHolidays for Chinese Mid-Autumn Festival and National Day in 2023