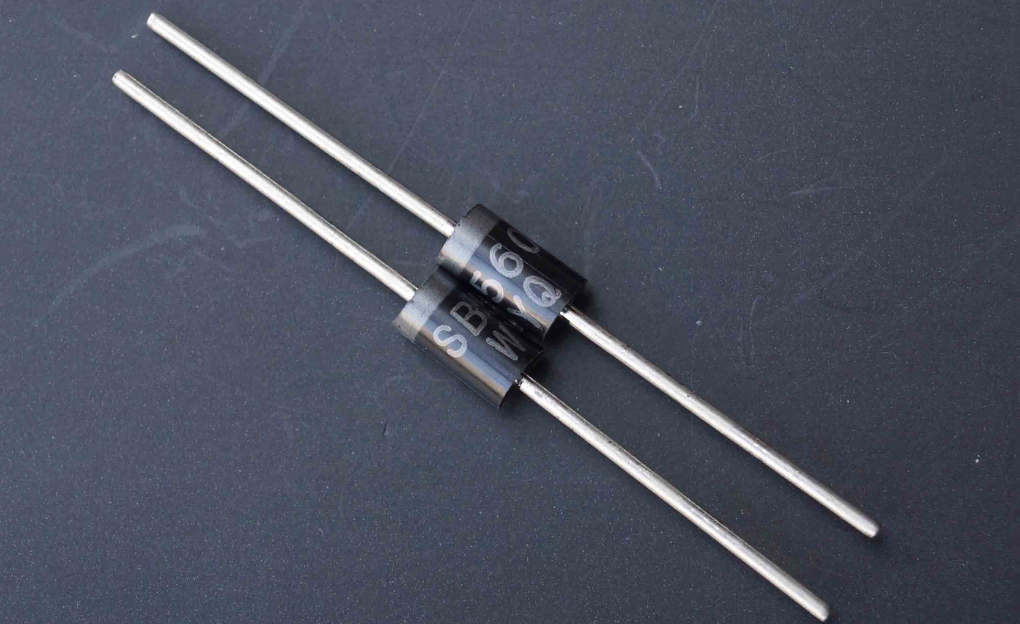

Seven major precautions for purchasing light -emitting diodes

Today I will share with you the things to consider when purchasing LEDs, including the material of the LED bracket, the size of the chip, the radiation power level, the material of the solder wire, the adhesive, the fluorescent powder, color separation, voltage division, and spectral separation.

1. Difference in LED bracket material:

Currently, there are various materials available for LED brackets, such as aluminum, brass, and purple copper. Aluminum brackets are the cheapest, while purple copper brackets are the most expensive, with a price difference of more than ten times. Even for purple copper brackets, the price can vary depending on whether they are silver-plated or not. Most of the brackets considered good in the market are made of silver-plated brass.

2. Difference in LED chip size:

The chip size is usually reported in mils. It is difficult to distinguish without a high magnification microscope. The larger the chip, the brighter the LED, and we can compare the chip size by calculating the chip area. For example, 23X10 indicates a chip area of 230 square mils. Using the chip area to distinguish the chip size is a good method.

3. Difference in LED chip radiation power level:

Even for chips of the same size, there can be a significant difference in the brightness of the resulting LED. Therefore, it is necessary to understand the radiation power level of the chip. The higher the radiation power, the brighter the LED produced.

4. Difference in solder wire material:

The chip and bracket are connected by gold wire. Currently, there are two choices of alloy wire and pure gold wire. Pure gold wire is the best, and the diameter of gold wire varies from 0.7, 0.9, 1.0, to 1.2. The thicker the gold wire, the lower the heat generation and the longer the lifespan. Therefore, it is necessary to ask about the material and diameter of the gold wire.

5. Difference in adhesive:

The fluorescent powder needs to be mixed with the adhesive and then applied to the chip. The quality of the adhesive will affect the light decay and color shift. Poor adhesive will yellow over time and increase light decay. Good adhesive is jelly-like.

6. Difference in fluorescent powder:

White LED is made of blue chip and fluorescent powder. Fluorescent powder is mainly divided into aluminum salt and silica salt. Aluminum salt performs better than silica salt. YAG is the most representative of aluminum salt, with stable performance and low light decay. The chemical stability of silica salt itself is poor, but its brightness is higher than that of YAG. Therefore, for products with stable performance, do not be fooled by the so-called high brightness, as this can be a big problem.

7. Specifications for spectral separation, color separation, and voltage division:

Spectral separation refers to the brightness classification of LEDs, which can be in terms of luminous flux or light intensity. For LED lighting, it is best to use luminous flux classification. It is recommended to choose LEDs based on their luminous efficiency, as high-efficiency products are more energy-saving and have longer lifespans.

Color separation refers to the color temperature classification, such as 3200K-3350K for one classification. Regular LED packaging factories will provide the BIN code for color temperature. The smaller the color temperature classification, the better, as the smaller the color temperature classification, the better the color consistency of the resulting LED.

Voltage division refers to the voltage classification of the chip, such as 3.0V-3.15V. For LEDs connected in series and parallel, the voltage classification should be controlled within 0.15V, so that the current distribution of the LED is uniform, which is beneficial to improve the lifespan of the light source.

Recent Posts

Company

About UsContact UsTerms & ConditionsPrivacy StatementPayment,Shipping & InvoiceRefund & Return PolicyWarranty PolicyFrequently asked questionHolidays for Chinese Mid-Autumn Festival and National Day in 2023