Comparison of advantages and disadvantages of solid capacitors and influencing factors

The solid-state capacitor, known as a solid-state aluminum electrolytic capacitor, is a type of capacitor that differs from ordinary capacitors, specifically liquid aluminum electrolytic capacitors, in terms of the dielectric materials used. While liquid aluminum capacitors utilize electrolyte as their dielectric material, solid capacitors employ electroconductive polymer materials as their dielectric material.

This distinction in dielectric materials is the key factor that sets solid-state capacitors apart from their liquid counterparts.

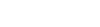

1 Introduction to Solid State Capacitors

Solid-state Capacitors

In response to the various issues associated with liquid electrolytic capacitors, solid aluminum electrolytic capacitors have emerged as a necessary solution. Since the 1990s, the use of solid conducting polymer materials as cathodes in aluminum electrolytic capacitors has led to significant advancements. Conductive polymer materials typically exhibit conductivity that is 2 to 3 orders of magnitude higher than that of electrolytes.

The application of aluminum electrolytic capacitors offers several advantages, including a reduction in equivalent series resistance (ESR) and improved temperature-frequency characteristics. Additionally, due to the excellent processability of polymer materials, they are easily packaged, further promoting the development of aluminum electrolytic capacitors.

On the market, two types of aluminum electrolytic capacitors are available: organic semiconductor aluminum electrolytic capacitors (OS-CON) and polymer conductor aluminum electrolytic capacitors (PC-AC) (PC-CON).

The structure of an organic semiconductor aluminum electrolytic capacitor is similar to that of a liquid aluminum electrolytic capacitor, with both being available in straight-pin and vertical configurations.

The key difference lies in the cathode material used in solid aluminum polymer electrolytic capacitors, which utilizes an organic semiconductor extract. This effectively addresses issues such as electrolyte evaporation, leakage, and flammability. Furthermore, a solid aluminum polymer chip capacitor combines the characteristics of aluminum electrolytic capacitors and tantalum capacitors, resulting in a unique structure.

Similar to liquid aluminum electrolytic capacitors, solid aluminum polymers are predominantly available in chip form. A high-conductivity polymer electrode film is deposited on alumina as the cathode, while carbon and silver serve as extraction electrodes. This structure closely resembles that of solid tantalum electrolytic capacitors.

2 Solid State Capacitor Advantages

(1) High Stability: Solid aluminum electrolytic capacitors offer high stability, allowing them to operate reliably in high-temperature environments and improve motherboard performance. They are particularly suitable for power filters due to their stable impedance across a wide temperature range. This ensures a stable and abundant power supply, especially during overclocking.

Solid-state capacitors can maintain their electrical properties even at high temperatures. The capacitance of solid-state electrolytic capacitors changes by less than 15% over the entire temperature range, which is significantly better than liquid electrolytic capacitors. Additionally, the capacitance of solid-state electrolytic capacitors remains independent of the working voltage, allowing them to operate stably in environments with voltage fluctuations.

(2) Long Service Life: Solid-state aluminum electrolytic capacitors have an extremely long service life, exceeding 50 years. This is longer than that of liquid aluminum electrolytic capacitors. Furthermore, there is no risk of breakdown or concerns about liquid electrolyte drying and leakage, which could affect the stability of the motherboard. Solid-state electrolytes do not expand or burn like liquid electrolytes at high temperatures. Even if the temperature exceeds the capacitor's limit, it will simply melt without causing the capacitor metal shell to burst, ensuring safety.

The service life of an electrolytic capacitor is directly influenced by the working temperature. The advantages of solid-state electrolytes result in a longer service life compared to liquid electrolytic capacitors under different temperature conditions.

(3) Low ESR (Equivalent Series Resistance) and High mA rms: Low ESR and high mA rms are important characteristics of capacitors. A lower ESR enables faster charge and discharge speeds, which directly affects the decoupling performance of the microprocessor power supply circuit, particularly in high-frequency circuits. This is where the biggest difference between solid-state electrolytic capacitors and liquid capacitors can be observed.

Solid aluminum electrolytic capacitors have lower ESR and dissipate less energy under high-power operation conditions. They can effectively absorb high-amplitude voltage between power lines in a circuit and prevent interference to the system. When the CPU transitions from a low-power state to a full load state, the power required for this switch (typically less than 5 milliseconds) comes from the CPU power supply circuit. The high-speed charge-discharge characteristic of solid-state capacitors allows them to instantly output the high peak current, ensuring an adequate power supply and stable operation of the CPU.

3 Solid State Capacitor Types

Capacitors can be categorized into three types based on the dielectric medium: inorganic dielectric capacitors, organic dielectric capacitors, and electrolytic capacitors.

1. Inorganic Dielectric Capacitors:

Inorganic dielectric capacitors include ceramic capacitors and mica capacitors. Ceramic capacitors are commonly found in CPUs and offer excellent overall performance. They can be used in high-frequency devices operating in the GHz range, such as CPUs and GPUs. However, due to their advanced capabilities, ceramic capacitors tend to be expensive.

2. Organic Dielectric Capacitors:

Organic dielectric capacitors, such as thin-film capacitors, are often used in applications where precision, high-temperature resistance, and high-pressure resistance are required. These capacitors are commonly found in loudspeakers.

3. Electrolytic Capacitors:

Electrolytic capacitors are commonly known as aluminum capacitors. Traditionally, the classification of electrolytic capacitors was based on the anode material, such as aluminum, tantalum, or niobium. However, this method of judging capacitance performance solely based on the anode material is outdated. Nowadays, the performance of electrolytic capacitors is primarily determined by the electrolyte and cathode materials. Electrolytic capacitors can be further classified based on the cathode materials, including electrolyte, manganese dioxide, TCNQ organic semiconductors, solid polymer conductors, and more.

These classifications help differentiate the various types of capacitors available in the market. It is important to consider the specific requirements of the application when selecting the appropriate capacitor type.

4 Brief Analysis of Advantages and Disadvantages of Solid Capacitors

Advantages:

1. Improved Safety: Solid capacitors use a polymer dielectric instead of liquid electrolyte, making them less prone to explosion. The solid-state dielectric has a higher boiling point of around 350 degrees Celsius, making it highly unlikely to burst.

2. Lower Equivalent Series Resistance (ESR): Solid capacitors exhibit a weak ESR in high-frequency operation, resulting in lower impedance and less heat generation. This property is most noticeable between 100KHz and 10MHz.

3. Temperature Stability: Traditional electrolytic capacitors are sensitive to temperature and humidity variations, leading to reduced stability at extreme temperatures. In contrast, solid capacitors can maintain an ESR as low as 0.004-0.005 ohms between -55 and 105 degrees Celsius, ensuring stability across a wide temperature range.

4. Minimal Capacitance Loss at Low Temperatures: Liquid capacitors experience a decrease in capacitance value at lower temperatures, with a decrease of around 13% at -20 degrees Celsius and 37% at -55 degrees Celsius. Solid capacitors, on the other hand, exhibit less than 5% capacitance loss at -55 degrees Celsius, making them more resistant to the harmful effects of low temperatures.

5. Longer Lifespan: Solid capacitors have a longer lifespan compared to electrolytic capacitors. At 105 degrees Celsius, both types of capacitors have a similar lifespan of 2000 hours. However, as the temperature decreases, the lifespan of solid capacitors increases even more. Solid capacitors can last up to 23 years, which is nearly six times longer than electrolytic capacitors.

Disadvantages:

1. Lower Low-Frequency Response: Solid capacitors do not perform as well as electrolytic capacitors in terms of low-frequency response.

2. Capacity Attenuation: Both solid and electrolytic capacitors experience capacity attenuation over time. While the capacity of circuit boards with solid capacitors fluctuates slightly, it can lead to power supply ripples and improper CPU functioning.

3. Maintenance Challenges: Identifying faulty solid capacitors can be challenging due to their multiple connections in the CPU power supply. In maintenance, it is common practice to remove one of the capacitors (regardless of its condition) and replace it with a large-capacity capacitor, often an electrolytic capacitor, to quickly solve the problem.

5 FAQ

1. What is a solid state capacitor?

A solid state capacitor, also known as a conductive polymer aluminum electrolytic capacitor or polymer aluminum capacitor, is a high-level capacitor product. It uses a functional conductive polymer as the dielectric material, which greatly enhances its performance.

2. Are Solid Capacitors better?

Solid capacitors offer several advantages over electrolytic capacitors. They have a higher tolerance for higher temperatures and perform better with higher frequencies and currents. Solid capacitors also exhibit lower impedance at higher frequencies, resulting in improved stability and reduced heat generation compared to electrolytic capacitors.

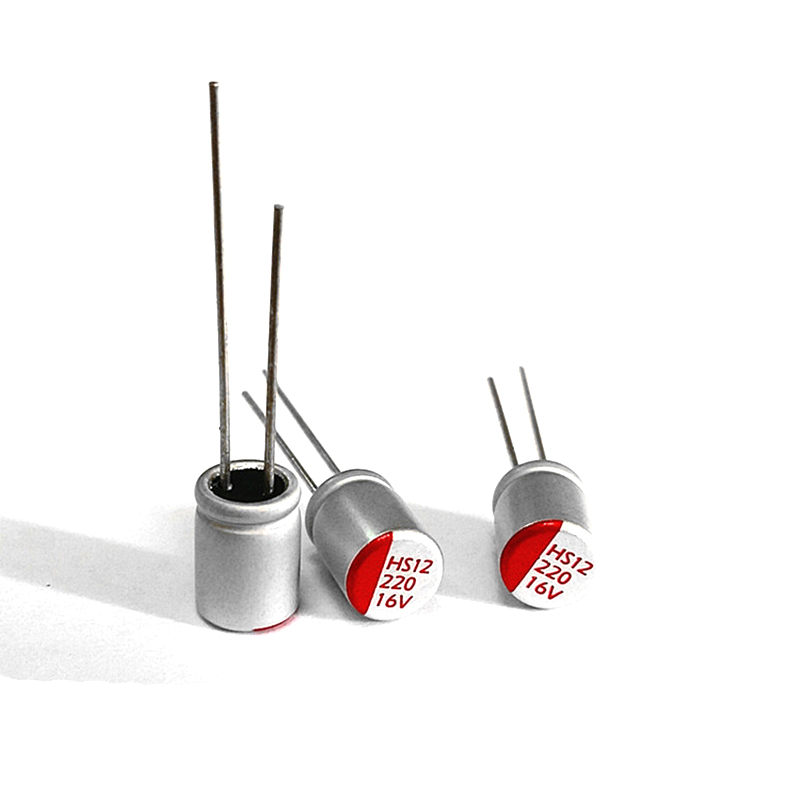

3. How do you read a solid state capacitor?

To read the capacitance value of a solid state capacitor, you can refer to the three-digit number printed on it. The third digit represents the number of zeros to add to the end of the first two digits. The resulting number represents the capacitance in pF. For example, if the number is 101, it represents 100 pF (10 with one additional zero).

4. What do you need to know about solid state capacitors?

Solid state capacitors are widely used in electronic and digital products. They are similar to common aluminum electrolytic capacitors and can be used as replacements for them. Some solid state capacitors are specifically designed to replace common tantalum capacitors. They offer improved performance and reliability.

5. Which is the best electrolytic capacitor for a motherboard?

Solid aluminum electrolytic capacitors are recommended for motherboards as they can improve performance. They have stable impedance over a wide temperature range, making them suitable for power supply filtering. These capacitors provide a stable and abundant power supply, which is especially important for overclocking.

6. How do you read a solid state capacitor?

To read the capacitance value of a solid state capacitor, refer to the three-digit number printed on it. The third digit indicates the number of zeros to add to the first two digits. This resulting number represents the capacitance in pF. For example, a capacitor labeled 101 represents 100 pF (10 with one additional zero).

7. What is the average lifespan of a capacitor?

The design lifetime of electrolytic capacitors is typically specified by manufacturers at the maximum rated ambient temperature, usually 105°C. This design lifetime can vary from as little as 1,000 hours to 10,000 hours or more, depending on the specific capacitor.

8. What metals are capacitors made of?

Electrolytic capacitors use different anode metals. Aluminum electrolytic capacitors utilize a high-purity etched aluminum foil with aluminum oxide as the dielectric. Tantalum electrolytic capacitors, on the other hand, use a sintered pellet of high-purity tantalum powder with tantalum pentoxide as the dielectric.

9. When should you use a capacitor?

Capacitors are commonly used in electronic circuits to block direct current while allowing alternating current to pass. They are also used in analog filter networks to smooth the output of power supplies.

10. How do I choose the right size capacitor?

When choosing a capacitor, consider the voltage and capacity values. These values are typically indicated on the capacitor itself. For example, if you need to charge a capacitor with 24V, ensure that the capacitor can support that voltage by selecting one with a voltage rating of at least 25V (plus an error margin).

Recent Posts

Company

About UsContact UsTerms & ConditionsPrivacy StatementPayment,Shipping & InvoiceRefund & Return PolicyWarranty PolicyFrequently asked questionHolidays for Chinese Mid-Autumn Festival and National Day in 2023