Powerful Protection from Payment to Delivery

Secure and Reliable Payment

Money Back Guarantee

Shipping and Delivery

After-Sales Service

Basic science and selection of automotive connectors

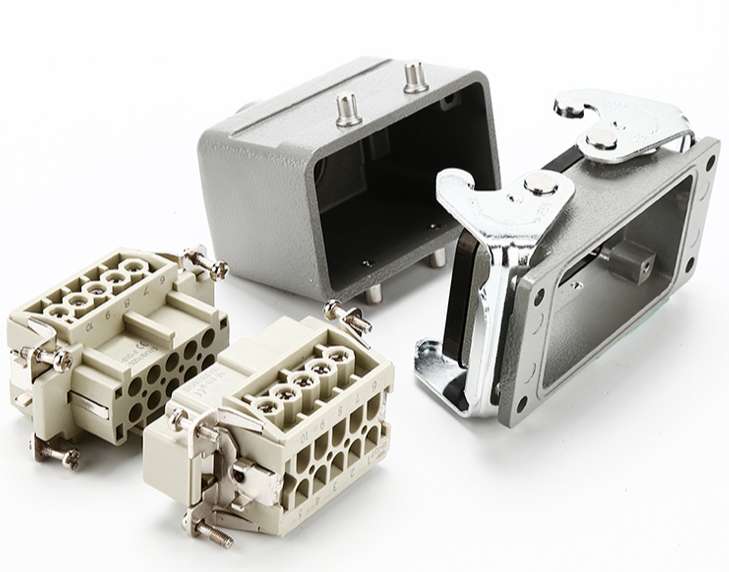

Automotive connectors are a crucial component for electronic engineering technicians, commonly used in various applications. Their primary function is to establish a communication bridge between blocked or isolated circuits in a circuit, allowing the current to flow and the circuit to achieve its intended function. The design and structure of automotive connectors continue to evolve, with four fundamental components making up their composition: contacts, shells (depending on the types), insulators, and accessories.

Automotive Connectors

Automobiles today require a vast array of connectors, with nearly 100 types used in general automobiles and hundreds used in a single model. With safety, environmental protection, comfort, and intelligence becoming increasingly important to consumers, the demand for automotive electronic products is on the rise, leading to a surge in the number of automotive connector applications.

Basic Structure

Automotive connectors rely on the four basic structural components to act as a bridge to make cars run stably. These components include contact pieces, shells, insulators, and accessories.

The contact piece is the core part of the automobile connector that completes the electrical connection function. A contact pair is generally composed of a male contact piece and a female contact piece. The male contact is a rigid part that can be cylindrical (round pin), square column (square pin), or flat (insert). Male contacts are typically made of brass and phosphor bronze. The female contact piece is the jack, which is the key part of the contact pair. It relies on the elastic structure to elastically deform when it is inserted into the pin to generate elastic force to form close contact with the male contact piece to complete the connection. There are many types of jack structures, including cylindrical type (split slot, necking), tuning fork type, cantilever beam type (longitudinal slotting), folding type (longitudinal slotting), box type (square jack) and hyperboloid wire spring jacks, etc.

The shell is the outer cover of the automotive connector, providing mechanical protection for the built-in insulating mounting plate and pins, and providing alignment when the plug and socket are inserted, thereby fixing the connector to the device.

The insulator, also known as the automobile connector base or insert, arranges the contacts according to the required position and spacing, and ensures the insulation performance with the shell. Good insulation resistance, withstand voltage performance, and ease of processing are the basic requirements for selecting insulating materials to be processed into insulators.

Accessories are divided into the structural part and the installation part. Structural accessories include retaining rings, positioning keys, positioning pins, guide pins, coupling rings, cable clamps, sealing rings, gaskets, etc. Mounting accessories include screws, nuts, spring rings, etc. Most of the accessories have standard parts and general parts.

Design Criteria

With the rapid development of the automotive industry, various functional components and components on cars are constantly developing towards intelligence, refinement, and reliability. The structural design, appearance design, and materials of automotive connectors also have higher requirements. Automotive connectors must comply with the USCAR-20 standard, which is the performance standard for automotive electrical connector systems. It specifies that the electrical connection surface of automotive connectors must always be reliable, including the following factors:

1) Connector contact material stability and reliability.

2) Stable forward force.

3) Stable voltage and current of the circuit.

4) Temperature requirements within the specified range, including ambient temperature and self-temperature rise.

5) Better robustness.

6) Must be the same as the connector used for high-speed and long-distance communication computers, and automotive connectors must be able to work reliably in harsh conditions.

7) Connector insertion force: less than 20.5kg.

8) Connector retention force: 2.5kg or higher.

9) Heat resistance: -40~120℃.

Automotive Connector Development Trends

The future of connector products lies in the "Miniaturization", "High Speed" and "Intelligence" of these products. Technological innovation in the industry is focused on the following areas:

1) Miniaturization Development: This technology aims to develop connectors that are smaller than 0.3mm, such as the new varieties of MINI USB series products. These connectors can be used for multi-contact expansion card slot connectors and have high accuracy and low cost.

2) Wireless Transmission: This technology is aimed at a variety of wireless device communication applications and has a wide range of applications.

3) Simulation Application Technology: This technology uses computer software such as AutoCAD and Pro/E program stress analysis software to simulate and analyze the mechanical, electrical, and high-frequency performance of product models. This helps to reduce the cost of product development failure and improve the development success rate.

4) Connector Intelligence Technology: This technology is currently used in DC series power connector products. Intelligent signal detection can be performed before power transmission to ensure that the positive and negative poles are turned on and the power is turned on after the plug is inserted in place. In the future, enterprises will need to develop similar intelligent technologies for other products.

5) Precision Connector Technology: This technology involves product design, process technology, and quality control technology. It includes precision mold processing technology, precision stamping and injection molding technology, and automated assembly technology.

6) Manufacturing Process Research: This area includes fine manufacturing process, integrate development technology of light source signal and electromechanical structure, and low temperature and low pressure molding process technology. These technologies can greatly improve the manufacturing efficiency and quality assurance capabilities of products.

Connector Selection

When designing an electrical connector system, several factors need to be considered to ensure optimal performance. These factors include electrical requirements, location/environment, standards, customer preference, regional preference, physical factors, and assembly.

1) Electrical Factor

The electrical requirements of a connector system include current requirements, wire diameter/insulation requirements, and steady state, cyclic, and transient current. These requirements determine the type of terminal/size of contact segment/plating, wire diameter/insulation requirements, and center distance of the connector.

2) Location/Environment

The location and environment play a significant role in determining the type of connector system to be used. Temperature, sealing, vibration, fluid compatibility, and humidity are some of the factors that need to be considered. For instance, engine compartments require sealed connectors with high-temperature resistance, while passenger compartments require unsealed connectors with lower temperature resistance.

3) Standard

Connector systems must meet specific standards, including customer standards, institutional standards, domestic standards, and international standards. The performance of the connector system must also meet system-level specifications, such as USCAR specifications for GM, Ford, and Chrysler.

4) Customer Preference

Customer preference is another factor that influences the design of a connector system. Some customers prefer cost-effective connector systems, while others focus on specific features such as terminal design/supplier, hole position of the connector, or terminal/plastic part suppliers.

5) Regional Preference

Regional preference also plays a role in the design of a connector system. North America prefers USCAR drawing/performance/design criteria, while Europe prefers two-piece contacts and long-term relationships between OEMs and suppliers. Asia traditionally follows Toyota's influence and focuses on assembly ability.

6) Physical Factors

Physical factors such as size, number of circuits, mating position, wire harness docking or equipment connection, mechanical main features, manual docking capability, and multiple types of connectors for high input/output applications also influence the design of a connector system.

7) Assembly

The assembly process is critical in ensuring optimal performance of a connector system. The insertion force of the connector, visual, audible, and tactile operational feedback for users must be considered during the assembly process.

Recent Posts

Company

About UsContact UsTerms & ConditionsPrivacy StatementPayment,Shipping & InvoiceRefund & Return PolicyWarranty PolicyFrequently asked questionHolidays for Chinese Mid-Autumn Festival and National Day in 2023